In today’s fast-paced world, the need for efficiency and innovation has never been more critical. You may have noticed that industries are increasingly turning to simulation technology as a means to enhance their operations. This technology allows you to create virtual models of real-world processes, enabling you to test and analyze various scenarios without the risks and costs associated with physical trials.

By leveraging simulation, you can gain insights that lead to better decision-making and improved outcomes across various sectors, from manufacturing to healthcare. Simulation technology encompasses a wide range of tools and methodologies, including computer-aided design (CAD), finite element analysis (FEA), and discrete event simulation (DES). These tools allow you to visualize complex systems and processes, making it easier to identify potential issues before they arise.

As you delve deeper into the world of simulation, you’ll discover how it can transform not only your approach to product development but also your overall productivity.

Key Takeaways

- Simulation technology plays a crucial role in enhancing productivity across various industries.

- It offers significant benefits in product development, manufacturing efficiency, and supply chain management.

- Simulation improves decision-making by providing detailed insights and predictive analysis.

- Integration with Industry 4.0 technologies amplifies the impact of simulation on operational processes.

- Overcoming implementation challenges is key to fully leveraging simulation technology’s future potential.

Understanding the Role of Simulation in Productivity

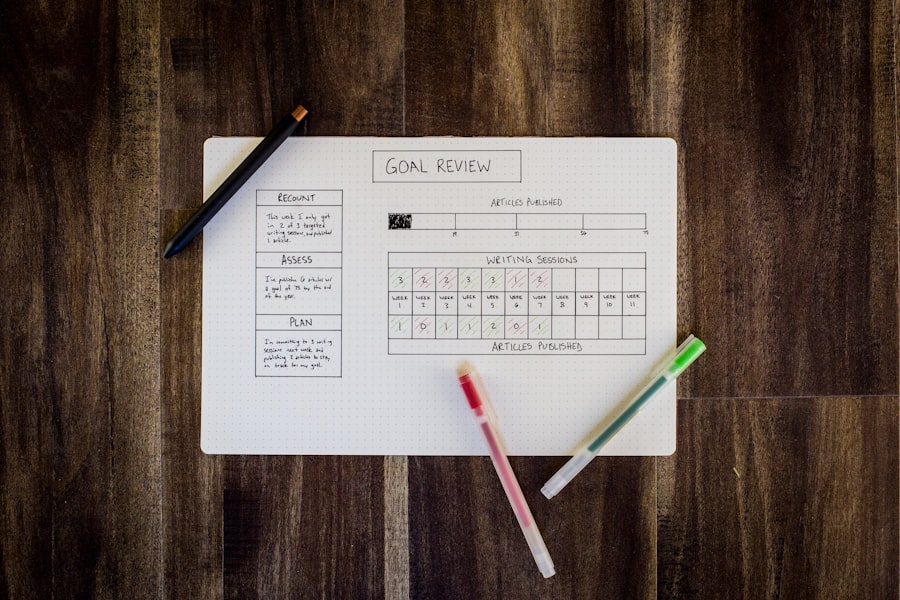

As you explore the role of simulation in productivity, it’s essential to recognize how it serves as a bridge between theoretical concepts and practical applications. By simulating real-world scenarios, you can analyze the impact of different variables on your processes. This analysis enables you to make informed decisions that can lead to significant improvements in efficiency and effectiveness.

For instance, when developing a new product, simulation allows you to test various designs and materials virtually, helping you identify the most effective solutions before committing resources to physical prototypes. Moreover, simulation technology empowers you to optimize workflows and processes. By modeling your operations, you can pinpoint bottlenecks and inefficiencies that may be hindering productivity.

This insight allows you to implement targeted changes that can streamline operations, reduce waste, and ultimately enhance your bottom line. In a competitive landscape, the ability to adapt quickly and efficiently is crucial, and simulation provides you with the tools necessary to stay ahead.

Benefits of Using Simulation Technology in Product Development

When it comes to product development, simulation technology offers a plethora of benefits that can significantly enhance your outcomes. One of the most notable advantages is the ability to reduce time-to-market. By utilizing simulation tools, you can rapidly iterate on designs and test various configurations without the need for costly physical prototypes.

This accelerated development process not only saves time but also allows you to respond more swiftly to market demands and customer feedback. Additionally, simulation technology fosters innovation by providing a safe environment for experimentation. You can explore unconventional ideas and test their feasibility without the fear of financial loss or resource depletion.

This creative freedom encourages teams to think outside the box and develop groundbreaking solutions that can set your products apart from the competition. As you embrace simulation in your product development process, you’ll likely find that it cultivates a culture of innovation within your organization.

How Simulation Technology Can Improve Efficiency in Manufacturing Processes

In the realm of manufacturing, efficiency is paramount. You may find that simulation technology plays a crucial role in optimizing production processes. By creating digital twins of your manufacturing systems, you can analyze performance metrics in real-time and identify areas for improvement.

Furthermore, simulation can help you streamline resource allocation. By modeling different production scenarios, you can determine the optimal use of machinery, labor, and materials.

This optimization not only minimizes waste but also maximizes output, ensuring that your manufacturing processes run smoothly and effectively. As you implement simulation technology in your operations, you’ll likely notice a marked improvement in overall productivity and profitability.

The Impact of Simulation on Supply Chain Management

| Metric | Description | Current Value | Projected Value (5 Years) | Unit |

|---|---|---|---|---|

| Simulation Speed | Time taken to complete a single simulation run | 2 hours | 30 minutes | Hours |

| Model Accuracy | Degree to which simulation results match real-world data | 85% | 95% | Percentage |

| Automation Level | Percentage of simulation processes automated | 40% | 90% | Percentage |

| Resource Utilization | Efficiency of computational resource usage | 70% | 90% | Percentage |

| Simulation Throughput | Number of simulations completed per day | 10 | 50 | Simulations/Day |

| Cost Efficiency | Cost per simulation run | 100 | 30 | Units |

Supply chain management is another area where simulation technology can have a profound impact. As you navigate the complexities of global supply chains, simulation allows you to model various scenarios and assess their potential outcomes. This capability is invaluable for identifying risks and developing contingency plans that can mitigate disruptions.

Moreover, simulation enables you to optimize inventory management by predicting demand fluctuations and adjusting supply levels accordingly. By simulating different supply chain configurations, you can identify the most efficient pathways for goods and materials, reducing lead times and costs.

Enhancing Decision-Making with Simulation Technology

One of the most significant advantages of simulation technology is its ability to enhance decision-making processes. When faced with complex challenges, having access to accurate data and predictive models can be a game-changer. You can use simulation tools to evaluate multiple scenarios and assess their potential impacts on your organization.

This analytical approach allows you to make informed decisions based on empirical evidence rather than intuition alone. Additionally, simulation fosters collaboration among teams by providing a shared platform for analysis and discussion. As you engage with colleagues from different departments, you can collectively explore various scenarios and their implications.

This collaborative environment not only leads to better decision-making but also encourages a culture of transparency and accountability within your organization.

As we move further into the era of Industry 4.0, simulation technology is becoming increasingly integral to modern manufacturing practices. You may have heard about the convergence of digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics with traditional manufacturing processes. In this context, simulation serves as a vital tool for integrating these technologies into cohesive systems.

By leveraging real-time data from connected devices, simulation allows you to create dynamic models that reflect current conditions in your manufacturing environment. This capability enables you to make proactive adjustments based on real-time insights, enhancing responsiveness and agility in your operations. As Industry 4.0 continues to evolve, embracing simulation technology will be essential for staying competitive in an increasingly complex landscape.

Overcoming Challenges in Implementing Simulation Technology

While the benefits of simulation technology are clear, implementing it within your organization may present challenges. One common hurdle is resistance to change among employees who may be accustomed to traditional methods. To overcome this resistance, it’s crucial to foster a culture that embraces innovation and continuous improvement.

Providing training and resources will empower your team members to understand the value of simulation and how it can enhance their work processes. Another challenge lies in integrating simulation tools with existing systems and workflows. You may need to invest time and resources into ensuring compatibility between different software platforms and data sources.

Collaborating with IT professionals and simulation experts can help streamline this integration process, allowing you to maximize the benefits of simulation technology without disrupting your operations.

Case Studies: Successful Implementation of Simulation Technology

Examining real-world case studies can provide valuable insights into the successful implementation of simulation technology across various industries. For instance, consider a leading automotive manufacturer that utilized simulation tools to optimize its assembly line processes. By creating digital twins of their production systems, they were able to identify bottlenecks and implement targeted improvements that resulted in a 20% increase in overall efficiency.

Another compelling example comes from the healthcare sector, where a hospital used simulation technology to model patient flow through its emergency department. By analyzing different scenarios, they were able to identify strategies that reduced wait times and improved patient satisfaction significantly. These case studies illustrate how organizations across diverse sectors are harnessing the power of simulation technology to drive productivity gains.

The Future of Simulation Technology and its Potential Impact on Productivity

Looking ahead, the future of simulation technology holds immense promise for enhancing productivity across industries. As advancements in computing power and data analytics continue to evolve, you’ll likely see even more sophisticated simulation tools emerge. These tools will enable you to create highly detailed models that account for an ever-increasing number of variables, leading to more accurate predictions and insights.

Moreover, as artificial intelligence becomes more integrated into simulation processes, you’ll find that these systems can learn from past experiences and adapt their models accordingly. This capability will further enhance decision-making by providing real-time recommendations based on historical data and current conditions. As you embrace these advancements, you’ll be well-positioned to leverage simulation technology as a cornerstone of your productivity strategy.

Harnessing the Power of Simulation Technology for Future Productivity

In conclusion, harnessing the power of simulation technology is essential for driving future productivity across various sectors. By understanding its role in enhancing decision-making, optimizing processes, and fostering innovation, you can position your organization for success in an increasingly competitive landscape. As you explore the benefits of simulation technology further, consider how it can be integrated into your operations to unlock new levels of efficiency and effectiveness.

As industries continue to evolve with advancements in technology, embracing simulation will be key to staying ahead of the curve. By investing in training, resources, and collaboration, you’ll empower your team members to leverage these tools effectively. Ultimately, by harnessing the power of simulation technology today, you’ll be paving the way for a more productive tomorrow.

In exploring the concept of future simulation productivity, one can gain valuable insights from the article available at Productive Patty. This article delves into innovative strategies and tools that can enhance efficiency and effectiveness in various tasks, making it a relevant resource for anyone interested in optimizing their productivity through simulation techniques.

WATCH THIS! 🧠 Why Your Breaks Are Actually Work (10x Breakthroughs)

FAQs

What is future simulation productivity?

Future simulation productivity refers to the use of advanced simulation technologies and methodologies to predict, analyze, and enhance productivity outcomes in various industries and sectors. It involves creating virtual models of processes, systems, or environments to forecast future performance and optimize efficiency.

How does future simulation improve productivity?

Future simulation improves productivity by allowing organizations to test different scenarios, identify potential bottlenecks, and optimize workflows without the risks and costs associated with real-world experimentation. This leads to better decision-making, reduced downtime, and increased operational efficiency.

What technologies are commonly used in future simulation productivity?

Common technologies include artificial intelligence (AI), machine learning, digital twins, virtual reality (VR), augmented reality (AR), and advanced data analytics. These tools help create accurate and dynamic models that can simulate complex systems and predict future outcomes.

In which industries is future simulation productivity most applicable?

Future simulation productivity is widely applicable across industries such as manufacturing, healthcare, logistics, construction, automotive, aerospace, and energy. Any sector that benefits from process optimization and predictive analysis can leverage simulation technologies.

What are the benefits of using future simulation for productivity?

Benefits include enhanced decision-making, cost savings, risk reduction, improved resource allocation, faster innovation cycles, and the ability to anticipate and mitigate potential issues before they occur in real-world operations.

Are there any challenges associated with future simulation productivity?

Yes, challenges include the need for high-quality data, the complexity of creating accurate models, computational resource requirements, and the necessity for skilled personnel to interpret simulation results and implement changes effectively.

How can organizations get started with future simulation productivity?

Organizations can start by identifying key processes that would benefit from simulation, investing in appropriate simulation software and technologies, training staff, and collaborating with experts in simulation and data analytics to develop and implement effective models.

Is future simulation productivity cost-effective?

While initial investments in technology and training can be significant, future simulation productivity often leads to long-term cost savings by reducing errors, minimizing downtime, and optimizing resource use, making it a cost-effective strategy over time.

What role does data play in future simulation productivity?

Data is critical as it feeds the simulation models, ensuring accuracy and reliability. High-quality, real-time data allows simulations to reflect actual conditions and produce meaningful predictions that can guide productivity improvements.

Can future simulation productivity be integrated with existing business systems?

Yes, future simulation tools can often be integrated with existing enterprise resource planning (ERP), manufacturing execution systems (MES), and other business software to provide a comprehensive view of operations and enhance overall productivity management.