The Four Lever Action Engine represents a fascinating innovation in the realm of mechanical engineering, particularly within the automotive industry. This engine type is characterized by its unique mechanism that utilizes four levers to convert linear motion into rotational energy, ultimately powering vehicles with enhanced efficiency. As you delve into the intricacies of this engine, you will discover how its design not only optimizes performance but also contributes to a more sustainable future in transportation.

The Four Lever Action Engine stands as a testament to human ingenuity, showcasing how innovative engineering can lead to significant advancements in vehicle technology. Understanding the Four Lever Action Engine is essential for anyone interested in the evolution of automotive mechanics. This engine type is not merely a variation of traditional engines; it embodies a distinct approach to energy conversion and mechanical efficiency.

By exploring its history, functionality, and applications, you will gain insight into why this engine is gaining traction in modern engineering discussions. As you navigate through this article, you will uncover the various facets of the Four Lever Action Engine, from its historical roots to its potential future developments.

Key Takeaways

- The Four Lever Action Engine is a unique mechanical design with distinct components and operation principles.

- It has a rich history that highlights its development and evolution in engine technology.

- Key advantages include improved efficiency and performance, while disadvantages may involve complexity and maintenance challenges.

- This engine type is used in specific applications where its unique features offer benefits over traditional engines.

- Ongoing advancements aim to enhance its functionality, impacting the future of automotive engineering.

History of the Four Lever Action Engine

The origins of the Four Lever Action Engine can be traced back to the early days of mechanical engineering when inventors sought to improve existing engine designs. The concept of using levers to amplify force and motion has been around for centuries, but it wasn’t until the late 20th century that engineers began to explore its application in engine technology. You will find that this exploration was driven by a desire for greater efficiency and reduced emissions, as traditional internal combustion engines faced increasing scrutiny for their environmental impact.

As you delve deeper into its history, you will discover that the Four Lever Action Engine emerged as a response to the limitations of conventional engines. Early prototypes were developed in research laboratories, where engineers experimented with various configurations and materials. Over time, these prototypes evolved into more sophisticated designs, leading to the first commercially viable models.

The journey of the Four Lever Action Engine reflects a broader trend in engineering: the continuous quest for innovation and improvement in response to societal needs.

How the Four Lever Action Engine Works

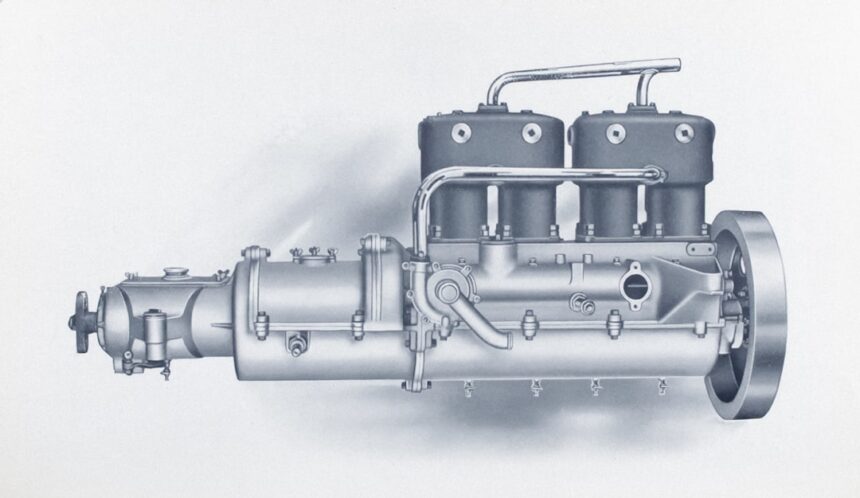

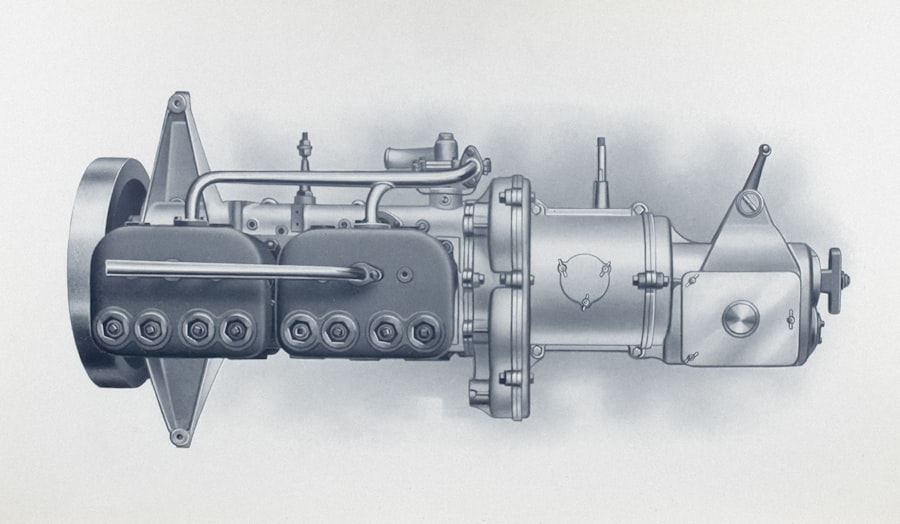

At its core, the Four Lever Action Engine operates on a principle that leverages mechanical advantage to enhance performance. When you examine its workings, you will notice that it employs four distinct levers that interact with one another to convert linear motion into rotational energy. This process begins when a force is applied to one of the levers, causing it to pivot and transfer energy through the interconnected levers.

The result is a smooth and efficient transfer of power that drives the engine’s output shaft. The beauty of this mechanism lies in its ability to optimize energy use. Unlike traditional engines that may waste energy through friction and heat, the Four Lever Action Engine minimizes these losses by ensuring that each lever’s movement is precisely calibrated.

As you explore this engine’s functionality further, you will appreciate how its design allows for greater torque and power output while maintaining lower fuel consumption. This efficiency not only benefits vehicle performance but also aligns with contemporary demands for greener technologies.

Components of the Four Lever Action Engine

| Component | Description | Function | Material | Typical Dimensions |

|---|---|---|---|---|

| Lever Arm | Primary lever that transmits force | Converts input force into mechanical motion | Steel or Aluminum Alloy | Length: 150-300 mm |

| Fulcrum | Pivot point for the lever | Supports lever and allows rotation | Hardened Steel | Diameter: 20-50 mm |

| Input Link | Link connecting input source to lever | Transfers input motion to lever arm | Steel or Composite | Length: 100-200 mm |

| Output Link | Link connecting lever to output mechanism | Delivers mechanical output from lever | Steel or Aluminum | Length: 120-250 mm |

| Spring Mechanism | Provides restoring force | Returns lever to initial position | Spring Steel | Variable based on design |

To fully grasp how the Four Lever Action Engine operates, it is essential to familiarize yourself with its key components. At the heart of this engine are the four levers themselves, each crafted from durable materials designed to withstand significant stress and strain. These levers are connected through a series of joints and pivots that allow for smooth movement and energy transfer.

As you consider these components, you will recognize that their design is critical to the engine’s overall efficiency and performance. In addition to the levers, other vital components include the input mechanism, which initiates motion, and the output shaft, which delivers power to the vehicle’s drivetrain. You will also find that various sensors and control systems are integrated into the engine to monitor performance and optimize operation.

These components work in harmony to ensure that the Four Lever Action Engine functions seamlessly, providing a reliable source of power for modern vehicles.

Advantages of the Four Lever Action Engine

One of the most compelling advantages of the Four Lever Action Engine is its remarkable efficiency. As you explore this aspect, you will find that its design allows for a more effective conversion of energy compared to traditional engines.

By reducing fuel consumption, vehicles equipped with this engine can contribute to lower greenhouse gas emissions, making them more appealing to eco-minded consumers. Another significant advantage lies in the engine’s compact design. The arrangement of levers allows for a smaller footprint compared to conventional engines, which can lead to lighter vehicles overall.

This reduction in weight not only enhances fuel efficiency but also improves handling and performance on the road. As you consider these benefits, it becomes clear that the Four Lever Action Engine offers a promising alternative for manufacturers looking to innovate while meeting regulatory standards and consumer expectations.

Disadvantages of the Four Lever Action Engine

Despite its many advantages, the Four Lever Action Engine is not without its drawbacks. One notable disadvantage is the complexity of its design. As you examine this aspect, you will realize that while the four-lever mechanism offers unique benefits, it also introduces challenges in terms of manufacturing and maintenance.

The intricate arrangement of levers and joints requires precise engineering and can be more difficult to assemble than traditional engine designs. Additionally, there may be concerns regarding durability and longevity. While advancements in materials have improved resilience, the moving parts within the Four Lever Action Engine are subject to wear over time.

As you consider these factors, it becomes evident that while this engine type holds great promise, it must overcome certain hurdles before it can achieve widespread adoption in the automotive market.

Applications of the Four Lever Action Engine

The versatility of the Four Lever Action Engine opens up a range of applications beyond traditional automotive use. As you explore this topic, you will find that its efficiency makes it suitable for various types of vehicles, including electric cars and hybrid models. Manufacturers are increasingly interested in integrating this engine into their designs as they seek ways to enhance performance while reducing environmental impact.

Moreover, beyond personal vehicles, there are potential applications in industrial machinery and equipment where efficient power generation is crucial. The ability to harness energy effectively can lead to significant cost savings and improved productivity in various sectors. As you consider these applications, it becomes clear that the Four Lever Action Engine has the potential to revolutionize not just personal transportation but also broader industrial practices.

Differences between the Four Lever Action Engine and Other Engine Types

When comparing the Four Lever Action Engine to other engine types, such as internal combustion engines or electric motors, several key differences emerge. One primary distinction lies in how energy is converted and utilized. Traditional internal combustion engines rely on fuel combustion to generate power, often resulting in inefficiencies due to heat loss and emissions.

In contrast, the Four Lever Action Engine’s mechanical advantage allows for a more direct conversion of energy with minimal waste. Electric motors also differ significantly from this engine type. While electric motors are known for their instant torque and quiet operation, they rely on electrical energy rather than mechanical leverage for power generation.

As you analyze these differences, you will appreciate how each engine type has its unique strengths and weaknesses, making them suitable for different applications within the automotive landscape.

Maintenance and Care of the Four Lever Action Engine

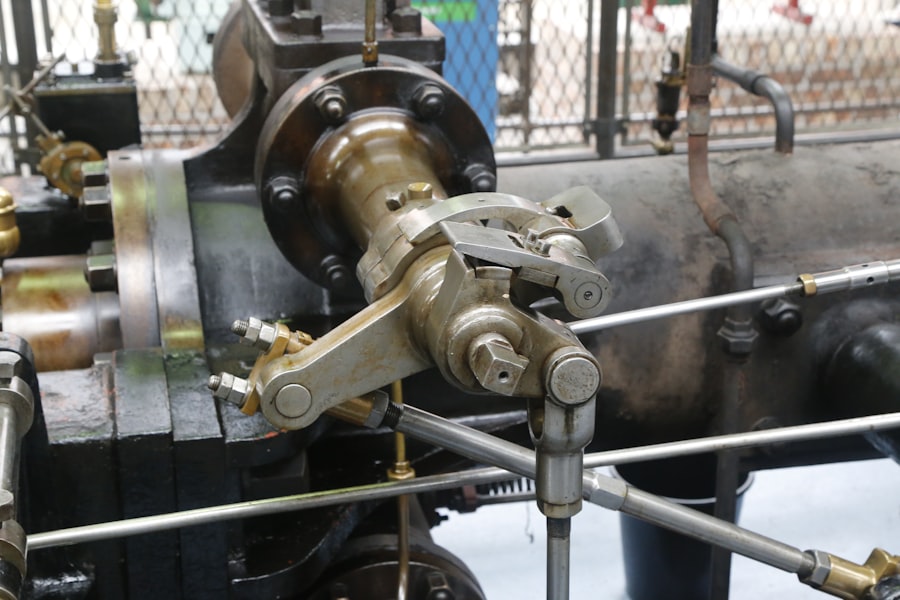

Proper maintenance is crucial for ensuring optimal performance and longevity of any engine type, including the Four Lever Action Engine. As you consider maintenance practices, you will find that regular inspections are essential for identifying wear on moving parts and ensuring that all components function smoothly. Lubrication plays a vital role in minimizing friction between levers and joints, so keeping up with oil changes and using high-quality lubricants can significantly extend the engine’s lifespan.

Additionally, monitoring performance metrics through integrated sensors can help detect any anomalies early on.

As you engage with these practices, you’ll recognize that taking care of this innovative engine is key to reaping its benefits fully.

Future Developments in Four Lever Action Engine Technology

Looking ahead, there are exciting possibilities for future developments in Four Lever Action Engine technology. Researchers are continually exploring ways to enhance efficiency further through advanced materials and innovative designs. As you consider these advancements, you’ll see that integrating smart technology could lead to even greater optimization of performance metrics and energy use.

Moreover, as global demand for sustainable transportation solutions grows, there may be increased investment in refining this engine type for broader applications across various industries. The potential for hybrid models that combine traditional power sources with Four Lever Action Engines could pave new pathways toward achieving cleaner transportation solutions. As you reflect on these future developments, it’s clear that this engine type holds significant promise for shaping the next generation of automotive technology.

The Impact of the Four Lever Action Engine on the Automotive Industry

In conclusion, the Four Lever Action Engine represents a remarkable advancement in automotive engineering with far-reaching implications for both performance and sustainability. As you’ve explored throughout this article, its unique design offers numerous advantages over traditional engines while also presenting certain challenges that must be addressed for widespread adoption. The potential applications across various sectors highlight its versatility and importance in meeting contemporary demands for efficient power generation.

As you consider its impact on the automotive industry, it’s evident that innovations like the Four Lever Action Engine are crucial for driving progress toward greener technologies and improved vehicle performance. By embracing such advancements, manufacturers can not only enhance their offerings but also contribute positively to environmental sustainability efforts worldwide. The journey of this engine type is just beginning; as technology continues to evolve, so too will its role in shaping the future of transportation.

The four lever action engine is a fascinating mechanism that showcases the principles of mechanical advantage and efficiency. For a deeper understanding of related concepts in engineering and mechanics, you can explore this insightful article on the topic at